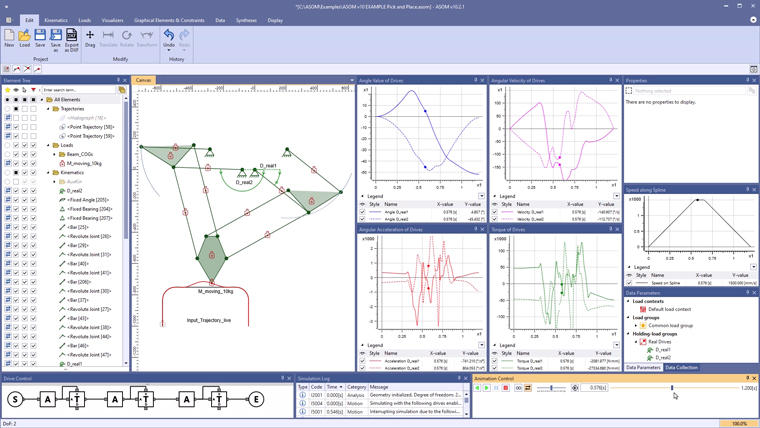

Deactivated drive elements sit at the locations of the real drives and measure the required drive profiles (angle over time, angular velocity, angular acceleration, required torque). In this way, even inverse kinematics can be calculated in ASOM in most cases (motion curve as input, drive values as output).

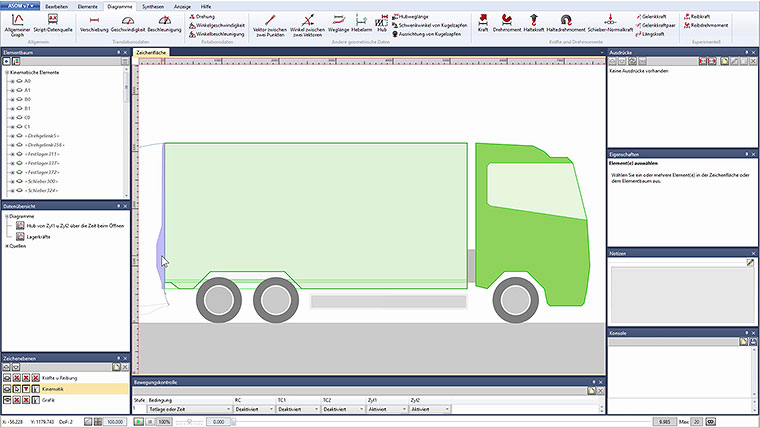

The system is suitably dimensioned and parameterized via constraints so that its necessary parallelisms or symmetries are maintained during all changes and the mechanism automatically adapts to any new joint or center of gravity positions. The movement curve (shown here in red) is implemented as a spline and can also be modified live.

The speed profile here is a speed trapezoid that is generated via three sections in the drive control (acceleration, constant speed, deceleration). All kinematic links are configured with masses and moments of inertia so that inertia effects are also taken into account when calculating the torques.