In this video series, we will show you the most common variants of the planar four-bar linkage, as well as their characteristics and special features. These variants can be derived from the theorem of Grashof.

Grashof’s condition for four-bar linkages states: The shortest link of a four-bar linkage can fully rotate in relation to its neighbouring links, if the sum of the lengths of the shortest and longest link is smaller – or at least equal, in the limit case – than the sum of the other two link lengths. The longest link in the four-bar linkage can be a neighbouring link of the shortest link or it can be situated opposite to it.

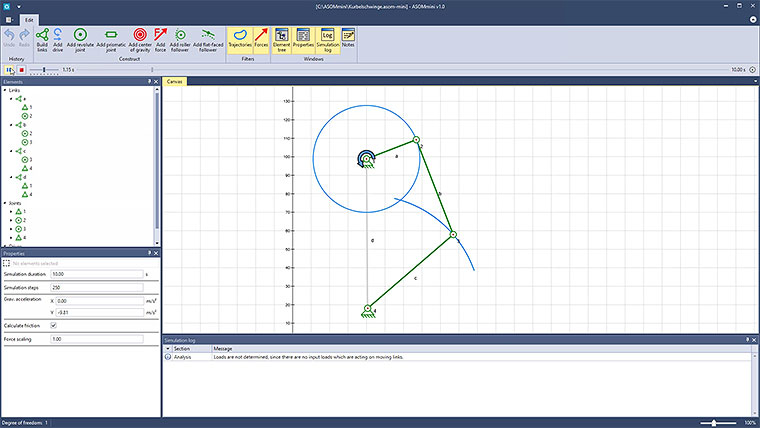

According to the usual conventions for four-bar linkages, we name the links and joints as follows: The shortest link is always designated a, the remaining links are designated b, c and d in a clockwise direction.

For joints, the following applies, analogously: Joint 1 is between a and d and from there the further numbering up to 4 is also done clockwise.

Alternatively, the fixed link is usually referred to as the frame and the link opposite from it as the coupler. The other two links are often called grounded links.

By deciding which of the links b, c and d is the longest, as well as by different choices for the frame, different types of four-bar linkages can then be derived.

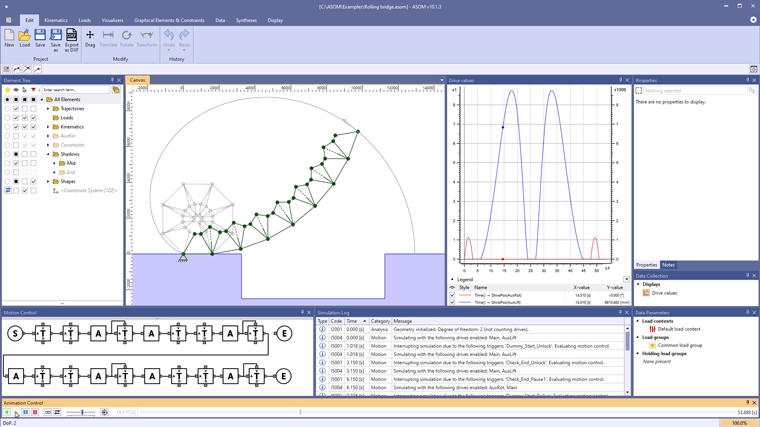

The start of our video series features the crank-rocker. The crank-rocker is probably the most frequently used type of four-bar linkage. It takes its name from the fact that one grounded link can perform a full turn (the crank) while the other can cover only a limited range of angles (the rocker).

Crank-rockers therefore, on the one hand, have to be four-bar linkages in which the shortest link is able to rotate fully according to Grashof’s rule. Thus a+b < c+d, a+c < b+d or a+d < b+c applies. In addition, a neighbouring link of a, i.e. b or d, has to be selected as the frame, so that a becomes a grounded link and can turn fully relative to the frame (and the coupler).

Here, the lengths a to d were chosen as follows:

a = 29 (min), b = 55, c = 61, d = 81 (max)

Thus, the following applies: a+d = 29+81 = 110 < 116 = 55+61 = b+c

The link d was chosen as frame. Therefore, the example is definitely a crank-rocker.

In ASOMmini, such linkages can be designed, simulated and analyzed kinematically very quickly and easily. They can also be modified and optimized in real time. The same also applies for more complex kinematic systems, which can also be implemented without difficulty using our software.