Kinematics of a hospital bed in ASOM

Hospital beds are equipped with two essential drives: one for adjusting the height of the entire bed and another for tilting the foot section. In reality, such systems often use spindle drives.

Through our example videos, we demonstrate how simple and straightforward the utilization of ASOM v10 is. Even for more complex problems, you will be able to quickly find an adequate solution.

Hospital beds are equipped with two essential drives: one for adjusting the height of the entire bed and another for tilting the foot section. In reality, such systems often use spindle drives.

The example shows a conceptual kinematic design for a truck tailgate lift or lift gate, as a linkage (degrees of freedom =2), driven by two hydraulic cylinders.

The example shows the externally visible components of a door closing system and the associated forces when the door is operated manually.

This case study demonstrates the deployment and retraction of an aircraft landing gear with bearing friction using the ASOM kinematics software. The model views the gear's movement along the aircraft axis and is applicable only during flight before touchdown.

Examples for the simulation of 4 different rotor shape variations for a Wankel engine with our kinematics software ASOM.

Using the example of a two-step folding ladder for a mobile home, it is shown how two systems can be organized in different folders in the element tree for the purpose of a direct comparison.

Example for the simulation of a Wankel engine with ASOM. For a triangular Wankel piston, the ratio between gear and gear ring must be a constant 2:3. This is ensured here by hidden constraints.

Example of a generic parallel pick-and-place mechanism in ASOM v10 with two degrees of freedom. The model is set up in such a way that its drive sits on the specified curve and drives the definition point over the curve ...

Example for the design of a mechanism for a flush-mounted retractable door handle with separate kinematic syntheses for the two partial systems (two syntheses “in series”).

In this example, the bearing forces at a cylinder piston of a two-stroke engine are determined in a simplified way.

In this example of a four-bar linkage, multiple manual force curves are determined in real time. The concept can of course also be applied to any other type of multi-bar linkage. The kinematic analysis can also be extended, e.g. to ...

This example shows how to implement joint friction for revolute joints in kinematic models in ASOM. With the aid of joint friction elements, a pin diameter and a friction coefficient can be managed for each revolute joint.

This example in the kinematics software ASOM v10 shows how to implement friction for slider/rail contacts in kinematic models, e.g. to realize the friction of a block on an inclined plane.

This example of a rolling bridge in ASOM v10 demonstrates how variants in the extended motion control and multiple shadow previews can help you better understand a model without having to play back the simulation completely after each modification.

These examples show that the kinematics software ASOM v10 also makes it possible to slide and roll arbitrary shapes on arbitrary shapes.

These examples show that the kinematics software ASOM v10 also makes it possible to have arbitrary shapes slide or roll on each other.

In this example, the ASOM v10 kinematics software simulates a back hatch with gas spring support that has a hat shelf as an additional feature.

In this example, the kinematics software ASOM v10 is used to simulate a possible mechanism for a hood with active pedestrian protection.

In this example, the kinematics software ASOM v10 simulates the mechanism for a car seat in automatic mode, operated by an electric motor.

In this example, the kinematics software ASOM v10 simulates the mechanism for a car seat in manual mode, operated by a lever.

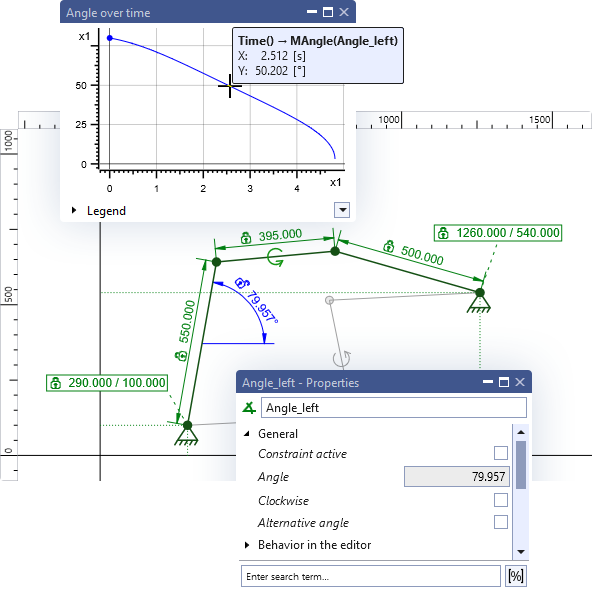

In this example, the interactive tool of two-point synthesis for four-bar systems is demonstrated in the kinematics software ASOM v10.