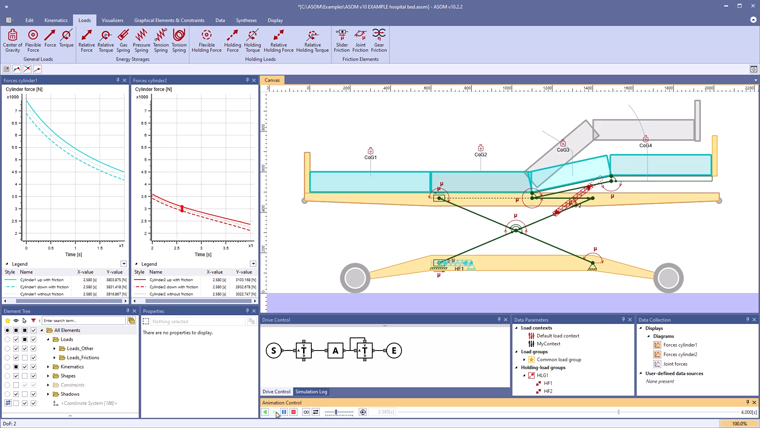

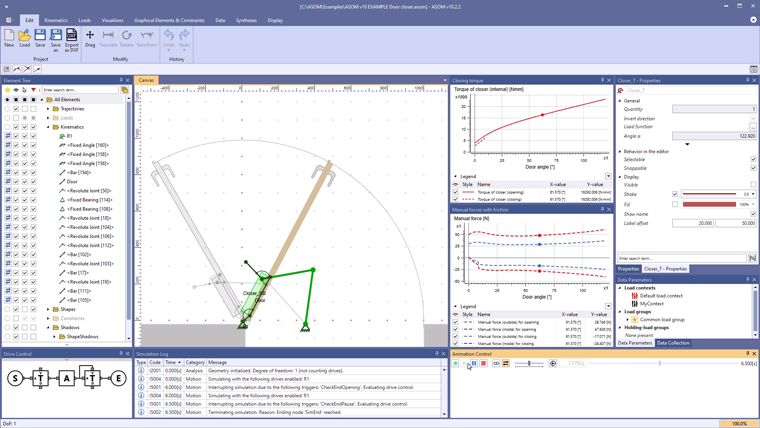

The movements of the individual bed components are simulated in real-time. During this process, all relevant forces, such as the actuation forces of the spindle drives as well as the joint and bearing forces at the connection points, are continuously calculated throughout the entire motion sequence. Additionally, all visual displays, such as diagrams or shadow previews, automatically update during the simulation. A particular highlight is that the friction in the joints, influenced by the joint forces, is also accounted for in the simulation.

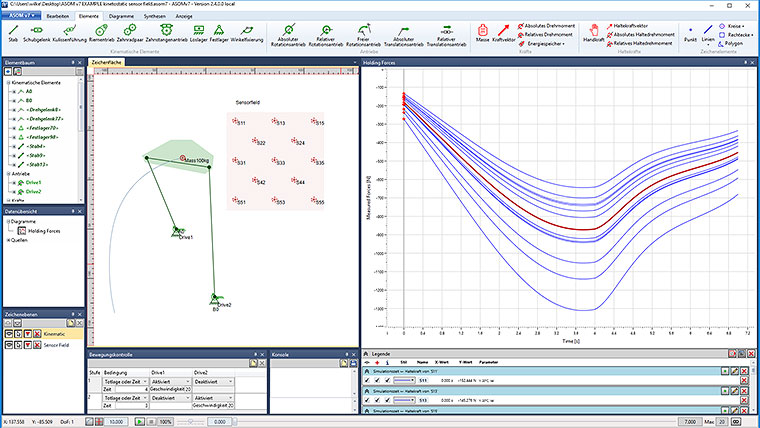

Such a drive system can be realistically modeled using holding force vectors and an optional support spring. These components can be adjusted to move logically and cohesively during editing. For more complex modeling requirements, ASOM also offers flexible solutions, such as the use of scripts.