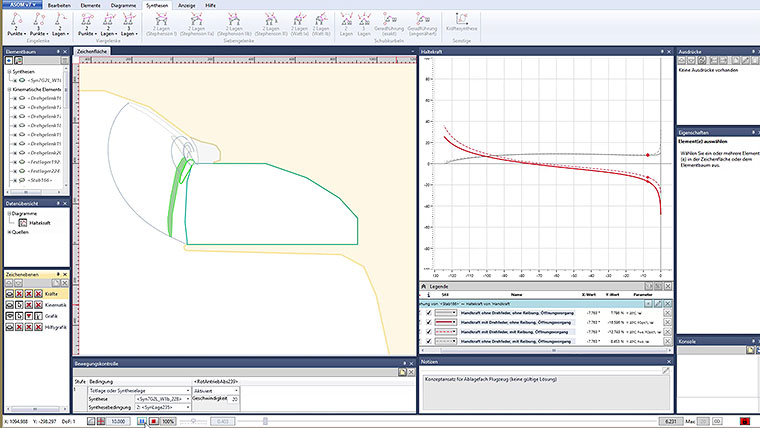

Taking all masses into account, the forces or manual forces required to actuate the mechanism are calculated once without friction and energy storages (here: compression springs) and once with friction and compression springs.

The friction is taken into account by means of individual friction coefficients at each rotary joint when calculating the required actuating force.

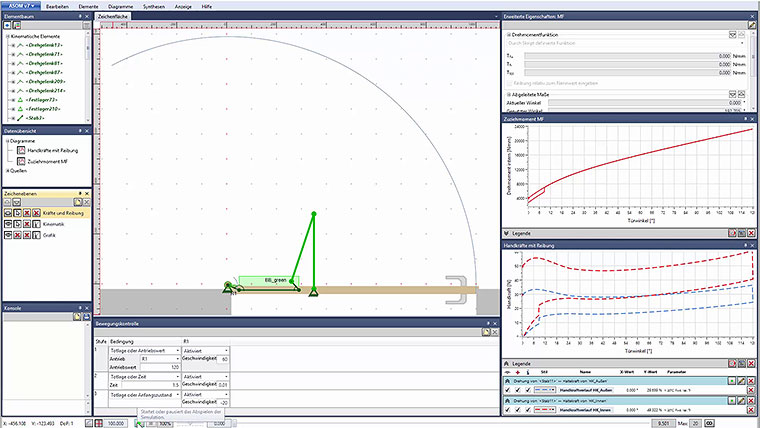

It is also briefly illustrated that with the help of the kinematic design software ASOMv7 it is possible to efficiently re-position a bearing joint, using the activated kinematic synthesis to automatically ensure that only such bearing positions are offered for which the desired starting and end positions of the table tops remain kinematically accessible.