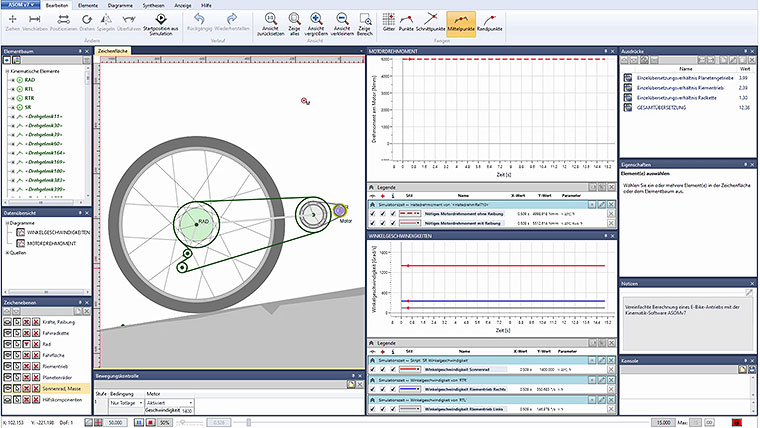

The example shows the essential kinematic structure of a typical E-Drive, starting with the drive pinion, which is connected to the sun gear of a planetary gear, continuing on to the planet gears and then via a belt drive or chain drive continuing on to the wheel, where the angular speed is finally converted into a translatory movement.

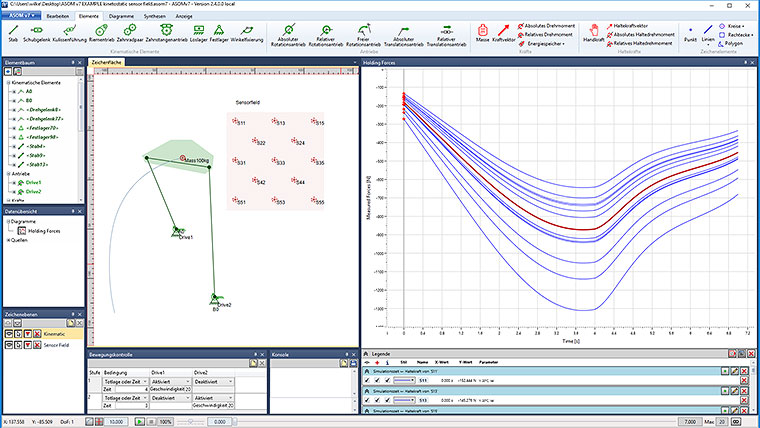

When varying a gear diameter – here on the drive chain, as an example – the kinematics software ASOMv7 adjusts the resulting moments and transmission ratios accordingly.

Varying the slope of the road also has an effect on the torques required for the drive.

ASOMv7 shows the calculation results with and without friction at the same time.